Optimizing Vertical Roller Mill Performance: CFD Study on Nozzle Ring Design with Modular Sickle-Shaped Splitters

DOI:

https://doi.org/10.37934/jartim.15.1.4352Keywords:

CFD, Discrete Phase Model, air flow, Vertical Roller MillAbstract

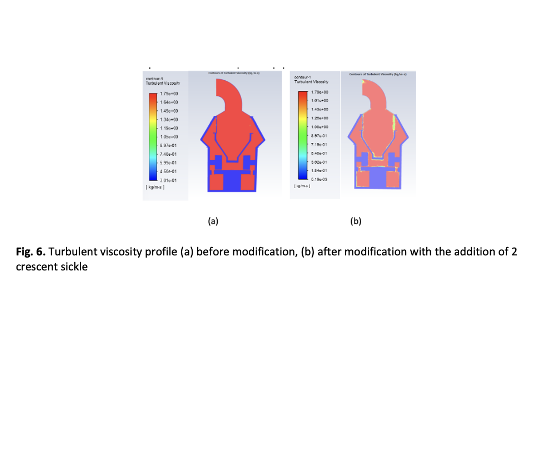

This study discusses modifying the geometric shape of the nozzle ring of the Vertical Roller Mill (VRM) to increase milling performance and energy efficiency. Computational Fluid Dynamics (CFD) and Discrete Phase Model (DPM) simulations are used to compare the design standard with the design modified, which is equipped with two water splitter elements in the form of a sickle. Simulation results show that modification produces a decline in peak speed gas flow up to 30%, reducing intensity turbulence by 14%, and increasing stability flow with the moving turbulent zone moving to the nearby area walls. In addition, the total energy consumption decreases by about 7%, extending the age of use components and allowing equipment to operate at its optimal efficiency. From the side performance particle, fraction “escaped” particles increase from 35.0% to 44.4%, indicating extension time stays and improves interaction with gas particles. Thus, this nozzle ring modification proved to increase the efficiency of transporting particles, stabilize the air flow, and reduce operational pressure. Because it is passive and modular, the design can be implemented without changing the existing structure of the channel air. Research. This recommends validating the field on the VRM scale industry and exploring alternative splitter forms to optimize performance further.