CFD Analysis of Electric Vehicle’s Battery Thermal Management System

Keywords:

EV, battery thermal management system, CFDAbstract

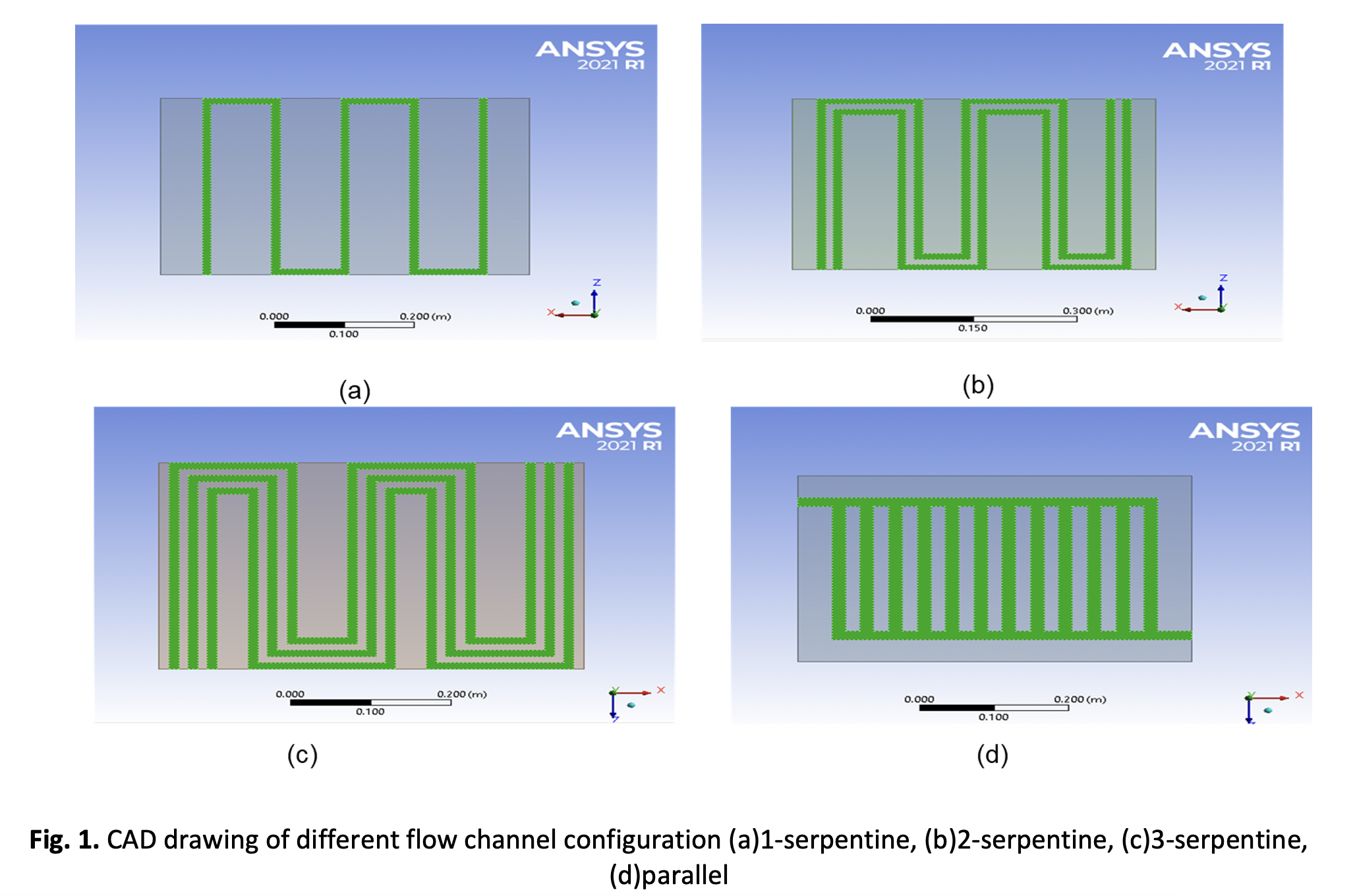

The main sources of CO2 emissions and environmental contamination are internal combustion engines and conventional gasoline. As a green energy solution for a cleaner future, electric vehicles are promoted. Lithium-ion batteries power EVs, but they have drawbacks such poor performance in extremely hot or cold temperatures, short electrode lifespans, and the potential for battery thermal runaway. Longevity of EVs depends on efficient battery thermal management systems (BTMs). In order to optimize the indirect liquid cooling system for EV batteries, this study highlights the critical roles that coolant selection, structural design, and channel configuration play. The impact of various coolants, different cold plate structures, and the number of channels were the three main parameters that were thoroughly addressed in this thorough CFD research employing a cold plate. The cold plate with serpentine-channel configuration, parallel and interdigited, is established in order to explore a straightforward and effective liquid cooling technique for the rectangular lithium-ion power batteries used in electric vehicles. The impact of coolant inlet temperature, channel arrangement, and cooling channel number on battery thermal management system cooling performance is then examined. The results of the numerical simulation show that the most effective cooling performance is achieved using a channel arrangement with three channels in a length-flowing direction. The maximum temperature can be lowered by 26 °C with this configuration as opposed to two or one channel. As the coolant's inlet temperature rises, so does the cooling system's maximum temperature. However, taking into account the cooling system's effectiveness and safety, there is a maximum restriction on the number of channels and the inlet temperature. The design of the cold plate for the thermal management system will benefit from the aforementioned outcome.