Innovative Semi-Automated Kuih Kapit Production: Leveraging Infrared Heating for Consistent Quality and Sustainability

DOI:

https://doi.org/10.37934/jartim.14.1.1019Keywords:

Infrared, peak wavelength, food qualityAbstract

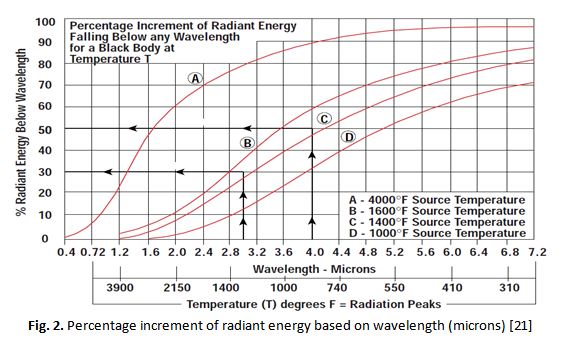

Traditional Southeast Asian snacks like kuih kapit are prized for their crunchy texture and intricate patterns, but making them by hand takes a lot of time and effort. High labor expenses, uneven product quality, and the cost of purchasing large-scale equipment make it difficult for small businesses to scale up production. By utilizing infrared (IR) heating technology, this study suggests a semi-automated production technique that tackles these problems. With an emphasis on energy economy and heat dispersion, the study optimizes the design of an infrared heater appropriate for kuih kapit molds using the Stefan-Boltzmann law. The process entails choosing materials with high emissivity and creating a small-scale, compact system. The proposed machine could perform at an optimal temperature of 160°C, or 3.6 microns, the peak infrared wavelength, by employing infrared (IR) heating. This preserves the snack's traditional quality, ensures consistent cooking, and lessens reliance on manpower. When compared to the conduction processes, IR technology shows that it offers constant heating, improving product consistency and consuming less energy. This creative method offers small businesses a sustainable and affordable alternative by fusing traditional craftsmanship with contemporary efficiency. In order to maximize manufacturing at different scales, future studies should concentrate on improving the design for affordability and investigating new IR wavelength configurations.