Innovative Ultrasonic Treatment for Enhancing Physicochemical and Foaming Properties of Raw Milk: Toward Sustainable Food and Agriculture

Keywords:

Ultrasonic, Non-Thermal Treatment, Raw Milk, Physicochemical Properties, Foaming PropertiesAbstract

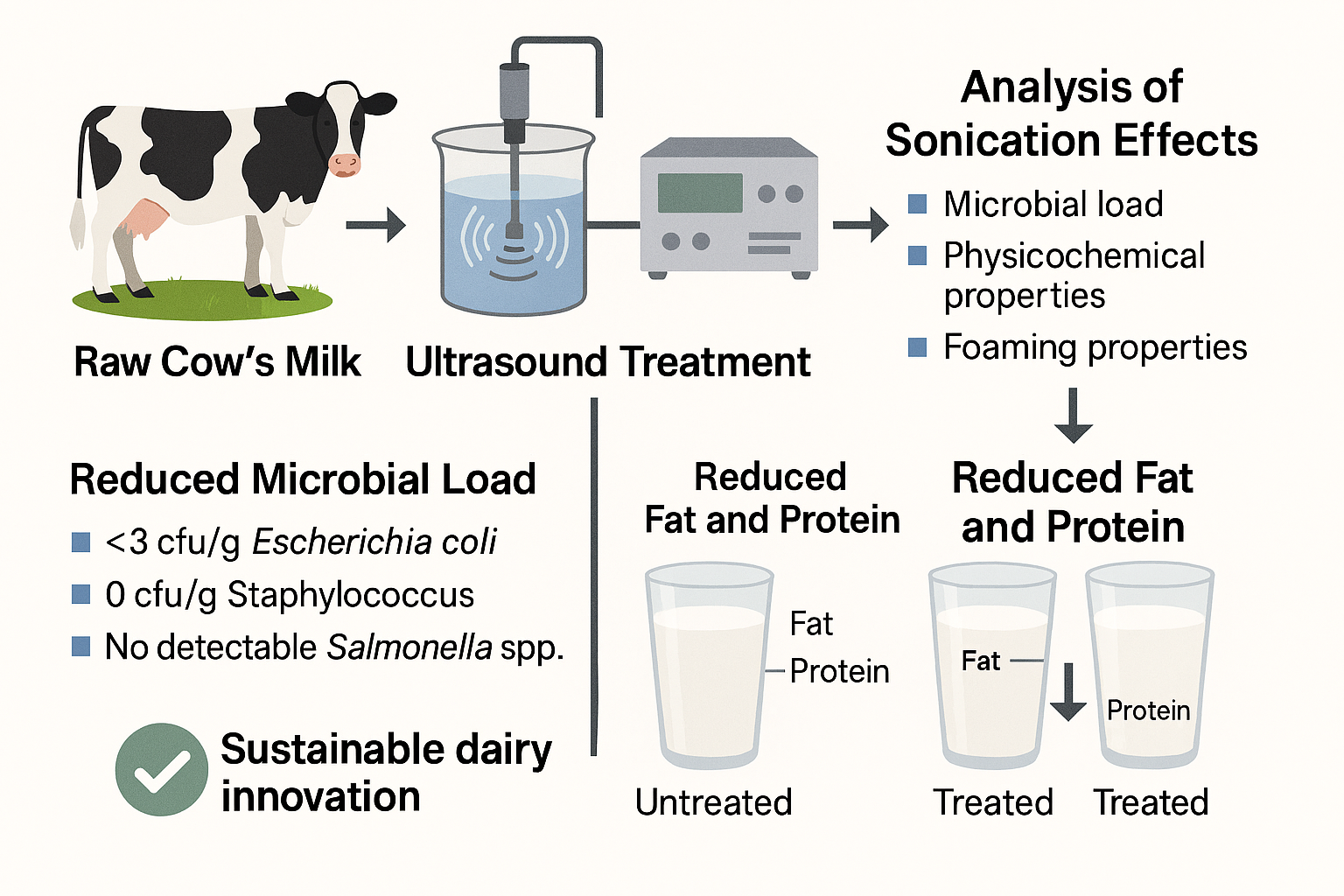

Raw cow’s milk is highly perishable and traditionally processed using thermal treatments, which can degrade its nutritional and functional properties. This raises a need for alternative methods that can ensure the safety and quality of raw cow’s milk. Ultrasound-treated cow’s milk is an emerging, innovative non-thermal technology that supports sustainable food processing by improving milk quality without high heat. This study aimed to analyse the effects of sonication on the microbial load, physicochemical, and foaming properties of raw cow’s milk, highlighting its potential in sustainable dairy innovation. The treated milk reduced fat (3.28%) and protein (3.08%) compared to untreated raw milk. Microbial analysis revealed that sonicated milk had <3 cfu/g of Escherichia coli, 0 cfu/g of Staphylococcus, and no detectable Salmonella spp. the total coliform count was significantly reduced to 1100 cfu/g depending on amplitude and time settings. Physicochemical assessments were conducted, including pH, viscosity, specific gravity, particle size distribution, zeta potential, titratable acidity, and colour. Statistical analysis using two-way ANOVA and post hoc Tukey’s test showed that milk treated at 40% amplitude for 6 minutes exhibited the most favourable quality outcomes across multiple parameters. These findings support using ultrasound as an innovative, energy-efficient processing method that enhances milk quality and contributes to sustainable food and agricultural practices.

References

[1] Z. Asefa, Physical Properties and Chemical Compositions of Raw Cow Milk in Milk Shades around Addis Ababa, Ethiopia, Asefa. Journal of Natural Sciences Research 9(19) (2019) 33–37. https://doi.org/10.7176/JNSR/9-19-04.

[2] A. Merwan, N. Amza, and M. Tamiru, Review on Milk and Milk Product Safety, Quality Assurance and Control. International Journal of Livestock Production 9(4) (2018) 67–78. https://doi.org/10.5897/IJLP2017.0403.

[3] S.B. Gregersen, L. Wiking, and M. Hammershøj, Acceleration of Acid Gel Formation by High Intensity Ultrasound is Linked to Whey Protein Denaturation and Formation of Functional Milk Fat Globule-Protein Complexes. Journal of Food Engineering 254 (2019) 17–24. https://doi.org/10.1016/j.jfoodeng.2019.03.004.

[4] C.F. Balthazar, A. Santillo, J.T. Guimarães, A. Bevilacqua, M.R. Corbo, M. Caroprese, R. Marino, E.A. Esmerino, M.C. Silva, R.S.L. Raices, M.Q. Freitas, A.G. Cruz, and M. Albenzio, Ultrasound Processing of Fresh and Frozen Semi-Skimmed Sheep Milk and its Effects on Microbiological and Physical-Chemical Quality. Ultrasonics Sonochemistry 51 (2018) 241–248. https://doi.org/10.1016/j.ultsonch.2018.10.017.

[5] S.N.B. Maklin, N.B. Julmohammad, S.B. Saallah, S.B. Saalah, N.B.M. Yaakub, M.D.B. Sintang, S.N.B.A. Rahman, and N.B. Julmohamad, Effect of Sonication Time on Physical and Foaming Properties of Pasteurized Milk. International Dairy Journal 161 (2024) 106137. https://doi.org/10.1016/j.idairyj.2024.106137.

[6] N.M. Yaakub, S.M.M. Kamal, N.L. Chin, N. Julmohammad, N. Therdthai, and A. Sulaiman, Optimisation of Non-Thermal Ultrasonication Process for Retaining Nutritional Quality in Cow milk: Effects of Fat Percentage and Treatment Parameters. Advances in Agricultural and Food Research Journal 5 (2024) a0000531. https://doi.org/10.36877/aafrj.a0000531.

[7] L.M. Carrillo-Lopez, I.A. Garcia-Galicia, J.M. Tirado-Gallegos, R. Sanchez-Vega, M. Huerta-Jimenez, M. Ashokkumar, and A.D. Alarcon-Rojo, Recent Advances in the Application of Ultrasound in Dairy Products: Effect on Functional, Physical, Chemical, Microbiological and Sensory Properties. Ultrasonics Sonochemistry 73 (2021) 105467. https://doi.org/10.1016/j.ultsonch.2021.105467.

[8] S. Karlović, T. Bosiljkov, M. Brnčić, D. Semenski, F. Dujmić, B. Tripalo, and D. Ježeka, Reducing Fat Globules Particle-Size in Goat Milk: Ultrasound and High Hydrostatic Pressures Approach. Chemical and Biochemical Engineering Quarterly 28(4) (2014) 499–507. https://doi.org/10.15255/CABEQ.2014.19400.

[9] A. Postelmans, B. Aernouts, J. Jordens, T. Van Gerven, and W. Saeys, Milk Homogenization Monitoring: Fat Globule Size Estimation from Scattering Spectra of Milk. Innovative Food Science & Emerging Technologies 60 (2020) 102311. https://doi.org/10.1016/j.ifset.2020.102311.

[10] T.M. Ho, P. Dhungana, B. Bhandari, and N. Bansal, Effect of the Native fat Globule Size on Foaming Properties and Foam Structure of Milk. Journal of Food Engineering 291 (2020) 110227. https://doi.org/10.1016/j.jfoodeng.2020.110227.

[11] AOAC SMPR® 2014.003 - AOAC INTERNATIONAL, AOAC INTERNATIONAL (2024). https://www.aoac.org/resources/smpr-2014-003-2/.

[12] P. Mudgil, B. Jumah, M. Ahmad, F. Hamed, and S. Maqsood, Rheological, Micro-Structural and Sensorial Properties of Camel Milk Yogurt as Influenced by Gelatin. LWT 98 (2018) 646–653. https://doi.org/10.1016/j.lwt.2018.09.008.

[13] Association of Official Analytical Chemists, Van Nostrand’s Encyclopedia of Chemistry, 2005. https://doi.org/10.1002/0471740039.vec0284.

[14] D. Sert, N. Akin, and E. Dertli, Effects of Sunflower Honey on the Physicochemical, Microbiological and Sensory Characteristics in Set Type Yoghurt during Refrigerated Storage. International Journal of Dairy Technology 64 (2010) 99–107. https://doi.org/10.1111/j.1471-0307.2010.00635.x.

[15] J.W. Fuquay, Encyclopedia of Dairy Sciences. Academic Press, Elsevier Ltd, 2011.

[16] T.M. Ho, T.H.A. Le, A. Yan, B.R. Bhandari, and N. Bansal, Foaming Properties and Foam Structure of Milk during Storage. Food Research International 116 (2018) 379–386. https://doi.org/10.1016/j.foodres.2018.08.051.

[17] Y. Yang, N. Nakada, R. Nakajima, M. Yasojima, C. Wang, and H. Tanaka, pH, Ionic Strength and Dissolved Organic Matter Alter Aggregation of Fullerene C60 Nanoparticles Suspensions in Wastewater. Journal of Hazardous Materials 244–245 (2012) 582–587. https://doi.org/10.1016/j.jhazmat.2012.10.056.

[18] M. Kaci, S. Meziani, E. Arab-Tehrany, G. Gillet, I. Desjardins-Lavisse, and S. Desobry, Emulsification by High Frequency Ultrasound using Piezoelectric Transducer: Formation and Stability of Emulsifier Free Emulsion. Ultrasonics Sonochemistry 21 (2013) 1010–1017. https://doi.org/10.1016/j.ultsonch.2013.11.006.

[19] N. Thirunavookarasu, S. Kumar, A. Anandharaj, and A. Rawson, Effect of Ultrasonic Cavitation on the Formation of Soy Protein Isolate – Rice Starch Complexes, and the Characterization and Prediction of Interaction Sites using Molecular Techniques. Heliyon 8 (2022) e10942. https://doi.org/10.1016/j.heliyon.2022.e10942.

[20] S. Shokri, F. Javanmardi, M. Mohammadi, and A.M. Khaneghah, Effects of Ultrasound on the Techno-Functional Properties of Milk Proteins: A Systematic Review. Ultrasonics Sonochemistry 83 (2022) 105938. https://doi.org/10.1016/j.ultsonch.2022.105938.

[21] W. Li, T.S.H. Leong, M. Ashokkumar, and G.J.O. Martin, A Study of the Effectiveness and Energy Efficiency of Ultrasonic Emulsification. Physical Chemistry Chemical Physics 20 (2017) 86–96. https://doi.org/10.1039/c7cp07133g.

[22] H. Sharma, F. Ozogul, E. Bartkiene, and J.M. Rocha, Impact of Lactic Acid Bacteria and their Metabolites on the Techno-Functional Properties and Health Benefits of Fermented Dairy Products. Critical Reviews in Food Science and Nutrition 63 (2021) 4819–4841. https://doi.org/10.1080/10408398.2021.2007844.

[23] G.O. Tona, I.C. Oladipo, and S.O. Oseni, Assessment of Physicochemical and Microbiological Quality of Jersey Cattle Raw Milk at Different Stages of Lactation. International Journal of Science and Research 5(6) (2016) 2610–2613. https://doi.org/10.21275/v5i6.28061602.

[24] S.N. Maklin, N. Julmohammad, S. Saallah, S. Saalah, M.J.H. Akanda, S.N.A. Rahman, and N. Julmohamad, Techniques for Nanoemulsion in Milk and its Application: A Review. International Food Research Journal 32(1) (2025). https://doi.org/10.47836/ifrj.32.1.01.

[25] Y. Sun, Y.H. Roos, and S. Miao, Comparative Study of Interfacial Properties and Thermal Behaviour of Milk Fat Globules and Membrane Prepared from Ultrasonicated Bovine Milk. Ultrasonics Sonochemistry 102 (2024) 106755. https://doi.org/10.1016/j.ultsonch.2024.106755.

[26] Y. Sun, Y.H. Roos, and S. Miao, Changes in Milk Fat Globules and Membrane Proteins Prepared from pH-Adjusted Bovine Raw Milk. Foods 11 (2022) 4107. https://doi.org/10.3390/foods11244107.

[27] L. Wu, J. Zhang, and W. Watanabe, Physical and Chemical Stability of Drug Nanoparticles. Advanced Drug Delivery Reviews 63 (2011) 456–469. https://doi.org/10.1016/j.addr.2011.02.001.

[28] S. Damodaran, Protein Stabilization of Emulsions and Foams. Journal of Food Science 70 (2006) R54–R66. https://doi.org/10.1111/j.1365-2621.2005.tb07150.x.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.