Improved Thermal Efficiency of Cooling of Offshore Wind Turbine Generators using Phase Change (PCM):CFD-Based Comparative Study

Keywords:

Cooling generators, offshore wind turbines, PCM, CFD, transient heat transfer, enthalpy–porosity, thermal efficiencyAbstract

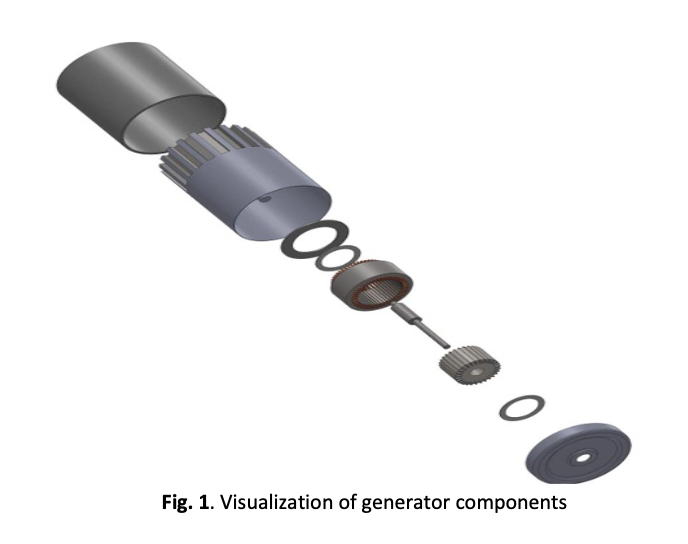

The maintenance and reliability of offshore wind turbine generators are impacted by heat accumulation in the corrosive and difficult-to-access marine environment, while conventional cooling often fails to withstand temperature surges and the creation of hot spots. This paper aims to determine the optimal PCM type, encapsulation design, and integration position. It also evaluates the extent to which PCM incorporation improves the thermal efficiency of an offshore generator cooling system. An enthalpy-porosity model was used in transient Computational Fluid Dynamics (CFD) simulations of the solid-liquid phase change material (PCM). At 50–100% load under forced and natural convection settings, three distinct PCM kinds (paraffin, hydrate salts, and eutectic mixes) as well as modifications to the encapsulation's placement and shape surrounding the stator coils and housing walls were investigated. PCM integration reduced the generator's peak temperature by 15–25% when compared to the reference without PCM; hydrate salts provided the best thermal homogeneity and the largest Tmax reduction (~22–25%); eutectic mixtures showed a balance between latent capacity and transient response (~20–23%); and paraffin offered the best cyclic stability despite a slower melting rate (~18–20%). Adjusted melting point, latent heat capacity, interfacial conductivity, and encapsulation design and location all affect final efficacy; prior to practical deployment, it is advised to improve heat transmission using conductive fillers or packed-bed structures.