Mechanical Insights through Finite Element Analysis: Flax Woven Fabric Reinforced Epoxy via Vacuum Infusion

DOI:

https://doi.org/10.37934/kjaas.2.1.110Keywords:

Tensile, flax woven fabric, vacuum infusion, Finite Element AnalysisAbstract

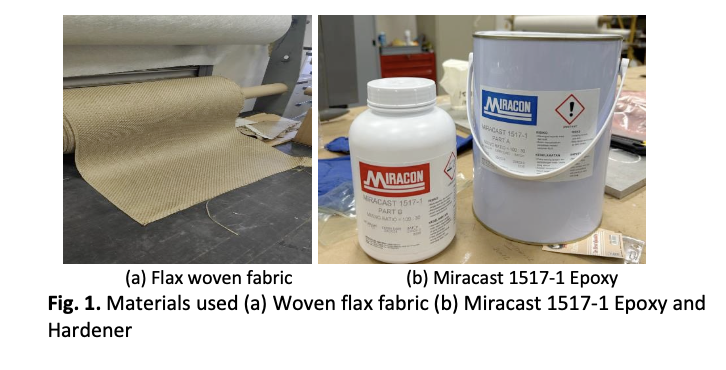

The growing demand for sustainable materials has driven interest in natural fiber-reinforced composites (NFRCs), with flax fibers emerging as a promising candidate due to their high specific strength, low density, and biodegradability. However, the widespread adoption of flax-based composites is hindered by challenges in manufacturing processes and the need for accurate predictive models to assess their mechanical performance. This study investigates the tensile properties of flax woven fabric reinforced epoxy composites fabricated using the vacuum infusion process (VIP) and evaluates their performance through both Finite Element Analysis (FEA) and experimental testing. The primary objective is to compare FEA predictions with experimental results, identify discrepancies, and propose improvements for predictive modeling. FEA predicted tensile strengths ranging from 216.31 MPa for 2 plies to 65.31 MPa for 8 plies, while experimental results showed lower values, ranging from 75.60 ± 5.37 MPa for 2 plies to 143.95 ± 13.76 MPa for 6 plies. Similarly, FEA overestimated tensile moduli, with values ranging from 4.33 GPa to 6.53 GPa, compared to experimental values of 2.83 ± 0.20 GPa to 3.41 ± 0.31 GPa. The largest discrepancies were observed for 2 plies and 8 plies, highlighting limitations in FEA models due to assumptions of ideal conditions, such as perfect fiber alignment and uniform resin distribution. These findings underscore the importance of considering real-world manufacturing variables, such as fiber misalignment, resin variability, and interfacial defects, which are often overlooked in FEA models. In conclusion, while FEA provides valuable theoretical insights, experimental results emphasize the need for refined modeling approaches that account for material imperfections and fabrication processes. Future work should focus on enhancing FEA models to improve the accuracy of predictions for flax-based composites, supporting their broader adoption in sustainable engineering applications.