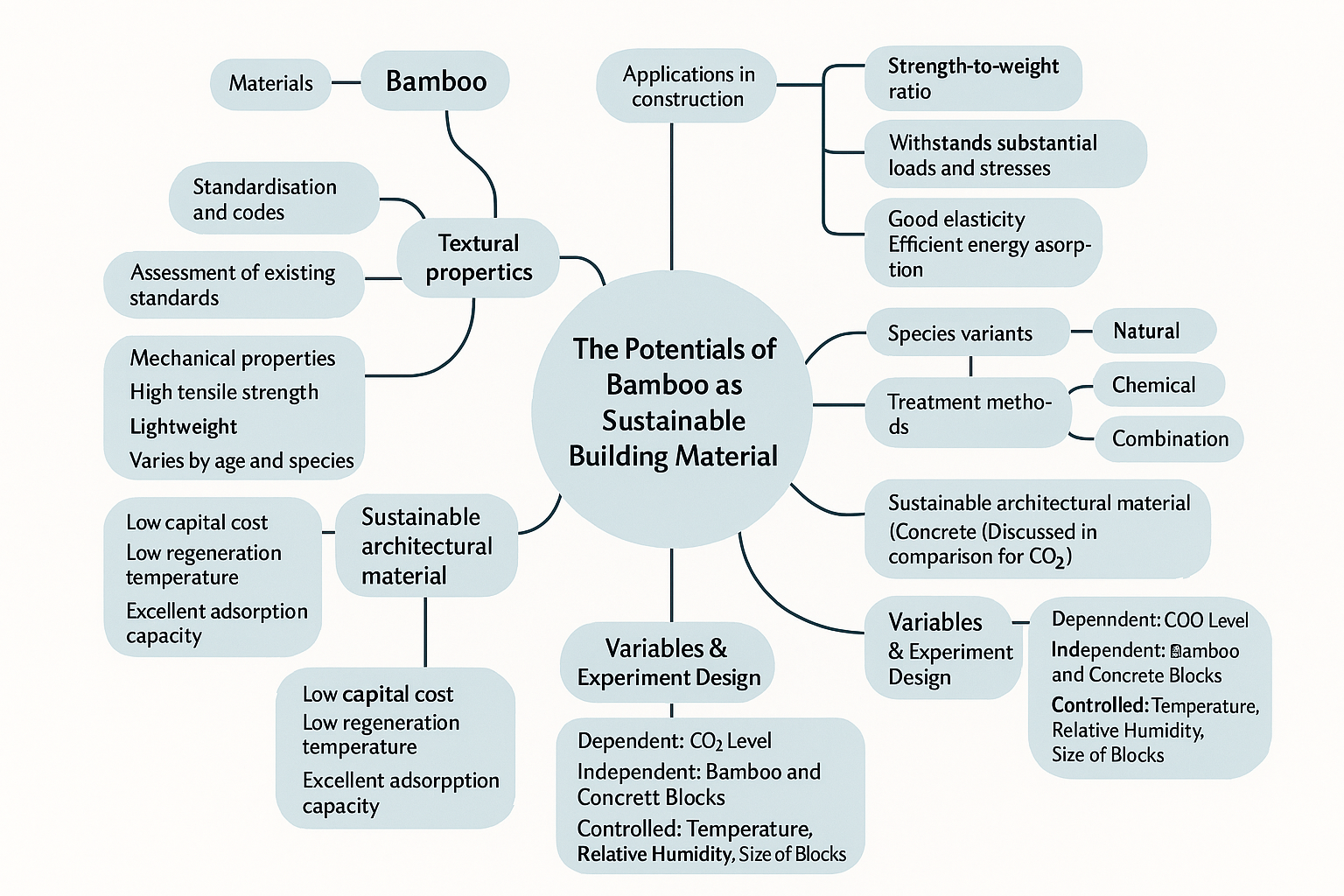

The Potentials of Bamboo as Sustainable Building Material: Carbon Dioxide Level Interrogating in an Enclosed Space

DOI:

https://doi.org/10.37934/progee.31.3.2734Keywords:

CO2 Level, Building Envelope, Bamboo and Concrete, Sustainable MaterialAbstract

The Construction industry is one of the vital industries that drives the economy of basically every country, providing jobs and opportunities in many aspects of the construction process. However, the construction industry is also one of the industries that produces the most CO2 around the globe, primarily due to the production of cement binder, normally Ordinary Portland Cement (OPC), an important concrete material. As concrete is a widely used construction material that is preferred by the industry due to its proven strength and durability, the CO2 emission also increases not only due to the production of its material, but also due to the properties of concrete, which may cause indoor comfort issues, leading to higher CO2 emission during the occupation stage. This highlights the importance of considering sustainable and eco-friendly materials in conventional constructions to reduce environmental effects. The hypothesis that “bamboo has lower CO2 levels as compared to concrete in an enclosed space” will be tested by using an IAQ meter to measure the CO2 level difference of both bamboo and concrete in a sealed plastic box. The results will be compiled and analysed to determine the difference in CO2 level between both materials in the plastic box to verify the hypothesis. This paper will acknowledge the researcher and industry stakeholders on the sustainable materials adaptation.

References

[1] M. Wackernagel, and W. Rees, Our Ecological Footprint: Reducing Human Impact on the Earth, New Society Publishers, 1998.

[2] UNEP Environment, UN, Building Materials and the Climate: Constructing a New Future, 2025. https://www.unep.org/resources/report/building-materials-and-climate-constructing-new-future (Accessed February 8, 2025).

[3] V. Kleinhenz, and D.J. Midmore, Aspects of Bamboo Agronomy. Advances in Agronomy 74 (2001) 99 – 153. https://doi.org/10.1016/S0065-2113(01)74032-1.

[4] US Department of Energy, Carbon Dioxide 101. https://netl.doe.gov/carbon-management/carbon-storage/faqs/carbon-dioxide-101 (Accessed February 8, 2025)

[5] Education, UCAR Center for Science, Center for Science Education. Carbon Dioxide, Center for Science Education. https://scied.ucar.edu/learning-zone/how-climate-works/carbon-dioxide (Accessed February 8, 2025).

[6] T. Wiedmann, and J. Minx, A Definition of ‘Carbon Footprint’, In: C. C. Pertsova, Ecological Economics Research Trends: Chapter 1, 2008: pp. 1 – 11.

[7] C.C. Wang, and X. Tan, Estimating Carbon Footprint in the Construction Process of a Green Educational Building, In: Proceedings of the 2012 International Conference on Construction and Real Estate Management, Kansas City, MO, USA, 2012: pp. 175 – 179.

[8] K. Ranjetha, U. Johnson Alengaram, A. M. Alnahhal, S. Karthick, W.J. Wan Zurina, and K.J. Rao, Towards Sustainable Construction Through the Application of Low Carbon Footprint Products. Materials Today: Proceedings 52 (2022) 873-881. https://doi.org/10.1016/j.matpr.2021.10.275.

[9] A. Hasanbeigi, P. Lynn Price, and L. Elina Lin, Emerging Energy-Efficiency and CO2 Emission-Reduction Technologies for Cement and Concrete Production: A Technical Review. Renewable and Sustainable Energy Reviews 16(8) (2012) 6220-6238. https://doi.org/10.1016/j.rser.2012.07.019.

[10] T. Hills, N. Florin, and P.S. Fennell, Decarbonising the Cement Sector: A Bottom-Up Model for Optimising Carbon Capture Application in the UK. Journal of Cleaner Production 139 (2016) 1351-1361. https://doi.org/10.1016/j.jclepro.2016.08.129.

[11] Rahman, Sherin Khadeeja, R. Al-Ameri, A Newly Developed Self-Compacting Geopolymer Concrete under Ambient Condition. Construction and Building Materials 267 (2021) 121822. https://doi.org/10.1016/j.conbuildmat.2020.121822.

[12] M.N. Nwodo, and J.A. Chimay, A Review of Life Cycle Assessment of Buildings using a Systematic Approach. Building and Environment 162 (2019) 106290. https://doi.org/10.1016/j.buildenv.2019.106290.

[13] EPA 2024, Introduction to Indoor Air Quality (IAQ), EPA, 2024. https://www.epa.gov/indoor-air-quality-iaq/introduction-indoor-air-quality.

[14] F.V.M. Adier, M.E.P. Sevilla, D.N.R. Valerio, and J.M.C. Ongpeng, Bamboo as Sustainable Building Materials: a Systematic Review of Properties, Treatment Methods, and Standards. Buildings 13(10) (2023) 2449. https://doi.org/10.3390/buildings13102449.

[15] A. Bala, and S. Gupta, Engineered Bamboo and Bamboo-Reinforced Concrete Elements as Sustainable Building Materials: A Review. Construction and Building Materials 394 (2023) 132116. https://doi.org/10.1016/j.conbuildmat.2023.132116.

[16] K. Chaowana, W. Supanit Wisadsatorn, and P. Chaowana, Bamboo as a Sustainable Building Material-Culm Characteristics and Properties. Sustainability 13(13) (2021) 7376. https://doi.org/10.3390/su13137376.

[17] Y. Ji, C. Zhang, X. J. Zhang, P. F. Xie, C. Wu, and L. Jiang, A High Adsorption Capacity Bamboo Biochar for CO2 Capture for Low Temperature Heat Utilization. Separation and Purification Technology 293 (2022) 121131. https://doi.org/10.1016/j.seppur.2022.121131.

[18] X. Xu, X. Peiyu, Z. Jianjun, L. Haitao, and X. Zhenhua, Bamboo Construction Materials: Carbon Storage and Potential to Reduce Associated CO2 Emissions, Science of the Total Environment 814 (2022) 152697. https://doi.org/10.1016/j.scitotenv.2021.152697.

[19] E.J. Zachariah, B. Sabulal, D.N.K. Nair, A.J. Johnson, and C.S.P. Kumar, Carbon Dioxide Emission from Bamboo Culms. Plant Biology 18(3) (2016) 400–405. https://doi.org/10.1111/plb.12435.

[20] Y. Luo, L. Zhang, M. Bozlar, Z. Liu, H. Guo, and F. Meggers, Active Building Envelope Systems Toward Renewable and Sustainable Energy. Renewable and Sustainable Energy Reviews 104 (2019) 470-491. https://doi.org/10.1016/j.rser.2019.01.005.

[21] X. Song, G. Zhou, H. Jiang, S. Yu, J. Fu, W. Li, W. Wang, Z. Ma, and C. Peng, Carbon Sequestration by Chinese Bamboo Forests and their Ecological Benefits: Assessment of Potential, Problems, and Future Challenges. Environmental Reviews 19(NA) (2011) 418-428. https://doi.org/10.1139/a11-015.

[22] E.A. Nurdiah, The Potential of Bamboo as Building Material in Organic Shaped Buildings. Procedia-Social and Behavioral Sciences 216 (2016) 30-38. https://doi.org/10.1016/j.sbspro.2015.12.004.

[23] M. Yadav, and A. Mathur, Bamboo as a Sustainable Material in the Construction Industry: An Overview. Materialstoday: Proceedings 43 (2021) 2872-2876. https://doi.org/10.1016/j.matpr.2021.01.125.

[24] M. Fahim, M. Haris, K. Khan, and S. Zaman, Bamboo as a Construction Material: Prospects and Challenges, Advances in Science and Technology. Research Journal 16(3) (2022) 165–175. https://doi.org/10.12913/22998624/149737.

[25] A. Hassan, M. Arif, and M. Shariq, Use of Geopolymer Concrete for a Cleaner and Sustainable Environment–A Review of Mechanical Properties and Microstructure. Journal of Cleaner Production 223 (2019) 704-728. https://doi.org/10.1016/j.jclepro.2019.03.051.

[26] B.N.A. Al-Gabri, A.B. Nabilah, F.N.A. Abdul Aziz, and I.A. Karim, Numerical Analysis of Out-of-Plane Deformation of Shear Wall. IOP Conference Series: Earth and Environmental Science 357(1) (2019) 012001. https://doi.org/10.1088/1755-1315/357/1/012001.

[27] W. Li, L. Xiaoshan, W.B. Ding, and Y.M. Xie, A Review of Formwork Systems for Modern Concrete Construction. Structures 38 (2022) 52–63. https://doi.org/10.1016/j.istruc.2022.01.089.

[28] Industry Code of Practice on Indoor Air Quality 2010 - Dosh. Department Of Occupational Safety and Health. https://www.dosh.gov.my/index.php/legislation/codes-of-practice/chemical-management/594-02-industry-code-of-practice-on-indoor-air-quality-2010/file (Accessed February 9, 2025).

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.