Improving Customer Satisfaction and Packaging Quality in Sunscreen Products: A Case Study on Failure Analysis and Design Optimization

DOI:

https://doi.org/10.37934/arbms.40.1.1426Keywords:

Sunscreen packaging, design quality improvement, universal testing machine, skincare industry, Ansys simulation, skincareAbstract

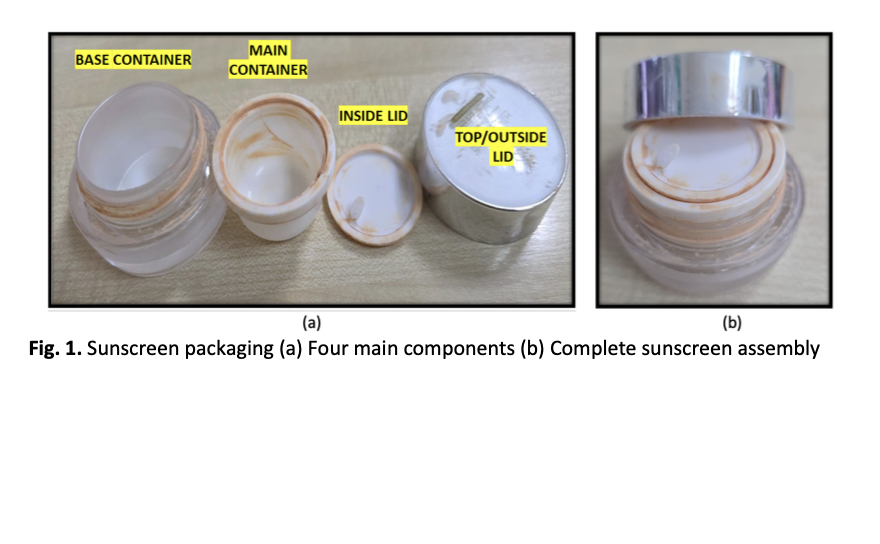

Sunscreen packaging plays a vital dual role in enhancing customer satisfaction and shaping brand perception, both of which are crucial to profitability in the skincare industry. This research was initiated in response to frequent customer complaints about leakage and breakage in a sunscreen product from a well-known skincare company (name withheld for confidentiality). Concerned about increasing dissatisfaction and potential harm to its reputation, the company commissioned a detailed investigation to determine the root causes of packaging failure. The study employed both experimental testing and simulation analysis to assess the structural integrity of the packaging. Using a universal compression testing machine, researchers identified a critical flaw in the cap material. Although labelled as aluminium, the cap was made from brittle plastic, revealing a significant quality and transparency issue in material sourcing. Simulation modelling further confirmed weaknesses in the cap's structural design, reinforcing the need for both material and design improvements. Beyond technical findings, the study uncovered broader implications for the company's quality control, supplier management, and customer experience strategies. The failure exposed a lack of material traceability and oversight, indicating systemic issues in procurement and production processes. Based on these insights, several recommendations were proposed. These include sourcing authentic and verified materials, redesigning the cap to withstand pressure and transport conditions, and adopting a more customer-centric approach to packaging innovation. The study emphasizes the importance of rigorous quality checks and supplier accountability to avoid future failures. This case highlights the crucial role of packaging integrity in maintaining brand loyalty, improving customer retention, and ensuring operational efficiency. It serves as a reminder that even minor packaging issues can have significant business consequences if not addressed proactively. In the competitive skincare market, where trust and quality are key differentiators, investing in robust, functional, and transparent packaging processes is essential for long-term success.