CFD Study of Flow Through a Converging Nozzle: Effect of Bore Diameter

DOI:

https://doi.org/10.37934/afhme.7.1.4048aKeywords:

CFD, converging nozzle, turbulent flow, pressure drop, bore diameterAbstract

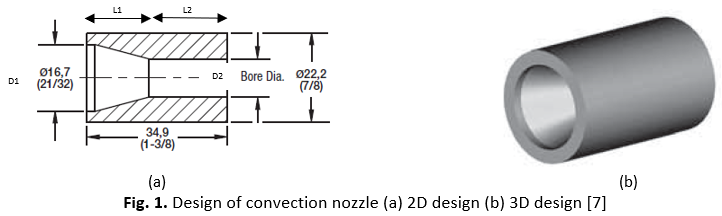

This study investigates the effects of nozzle bore diameter on the flow characteristics of a turbulent, incompressible fluid through converging nozzles, focusing on velocity and pressure distributions. Computational Fluid Dynamics (CFD) simulations were conducted using ANSYS Fluent to analyse three different nozzle bore diameters: 4 mm, 6 mm, and 9 mm, under identical inlet conditions of 1 m/s uniform velocity and a zero-pressure outlet boundary. The primary objective was to quantify the impact of nozzle geometry on performance metrics such as velocity, pressure distribution, and overall pressure loss. The results demonstrate a significant relationship between bore diameter and flow behaviour. As the bore diameter decreases, the fluid experiences greater flow acceleration, leading to higher exit velocities. The 4 mm nozzle produced the highest exit velocity, which was 423.3% higher than the 9 mm nozzle and 130.9% higher than the 6 mm nozzle. However, this increase in velocity was accompanied by a substantial pressure drop, with the 4 mm nozzle exhibiting 96.5% lower pressure than the 9 mm nozzle and 81.7% lower pressure than the 6 mm nozzle. These findings suggest that smaller nozzles enhance jet velocity and momentum, making them ideal for high-intensity applications such as waterjet cutting and abrasive blasting. In contrast, the 9 mm nozzle, while producing the lowest exit velocity, demonstrated the least pressure drop, with 81.1% lower pressure than the 6 mm nozzle and 96.5% lower pressure than the 4 mm nozzle. This indicates that larger nozzles are more hydraulically efficient, making them suitable for applications prioritizing energy conservation and uniform flow distribution, such as fluid transport and pumping systems. The 6 mm nozzle, offering a balance between the higher jet velocity of the 4 mm and the hydraulic efficiency of the 9 mm nozzle, represents a middle ground for applications that require moderate velocity with reduced energy loss. This study highlights the trade-offs between velocity and pressure, allowing engineers to make informed decisions when selecting nozzle sizes for specific industrial applications.