Predicting Specific Mechanical Energy (SME) in Composite Compounding Process: An Analysis of Area Under Graph Base Selection Effects

Keywords:

Specific Mechanical Energy, Regression, HomogeneousAbstract

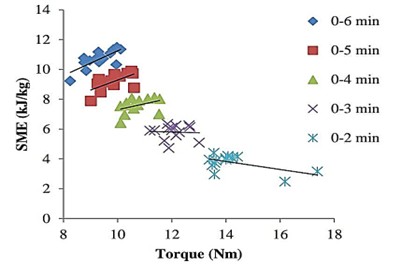

This study investigates the Specific Mechanical Energy (SME) of compounding processes, a crucial parameter in polymer composite manufacturing. SME can be derived from the area under the torque-time graph. However, when comparing different compounding processes, the basis for calculating this area, either on a same time basis or a same torque basis, can vary, potentially influencing the accuracy of SME prediction. This study aimed to evaluate the impact of this basis selection on the predictability of SME, using a regression equation and the data fitness value (R2). We calculated the area under the graph from 28 composite compounding processes, examining the overall SME as compounding progressed and SME for specific segments of the torque-time graph. Our main finding reveals that using the same torque basis consistently yields better R2 values than the same time basis. Specifically, R2 values improved for overall SME when analyzed with the same torque basis, whereas no improvement was observed with the same time basis. For segments of the area under the graph, the same time basis produced unreliable R2 values, while the same torque basis resulted in highly reliable R2 values exceeding 0.999. In conclusion, for compounding Polypropylene (PP)/kenaf core composites, the most effective and reliable method for comparing SME is using the same torque basis, particularly for analyzing specific area segments under the torque-time graph. This approach ensures greater predictability and accuracy in understanding the energy input during the compounding process.