A TOPSIS-Based Multi-Criteria Decision Framework for Mechanical Characterization of Polymer Matrix Composites

Keywords:

Polymer Matrix Composites, Multi-Criteria Decision-Making, TOPSIS, Mechanical Properties, Materials Selection, Interlaminar Shear Strength , Carbon-Based Fillers, Bio-Fillers, Composite Optimization, High-Stress Applications, Tensile Strength, Impact StrengthAbstract

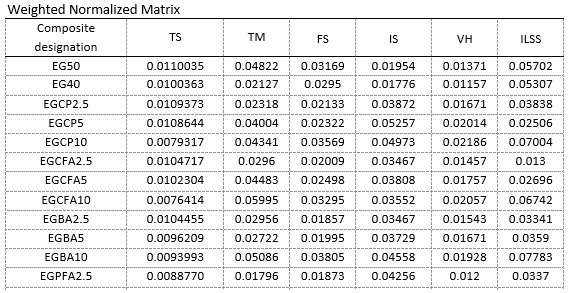

This study introduces a structured method for evaluating and prioritizing polymer matrix composites (PMCs) using Multi-Criteria Decision-Making (MCDM) techniques, specifically the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS). By incorporating mechanical properties such as tensile strength, modulus, impact strength, and interlaminar shear strength (ILSS), it offers a comprehensive framework for material assessment that goes beyond previous research which focused on limited properties or traditional methods. The research emphasizes the impact of different types and amounts of fillers on the performance of composites. Carbon-based fillers like BoA and CFACP consistently ranked higher due to their exceptional ILSS and impact strength, highlighting their superiority in high-stress applications. On the other hand, bio-fillers such as Marble Powder and Rice Husk Ash showed weaker mechanical properties and lower rankings. These findings provide valuable insights for professionals in industry, research, and academia, helping them select materials tailored for specific applications. By using TOPSIS in the MCDM framework, this study advances material science methodologies and demonstrates the benefits of evaluating materials based on multiple properties. The superior performance of carbon-based fillers compared to bio-fillers is essential for optimizing PMCs in high-stress environments. This research not only assists in the selection of advanced materials but also contributes to the ongoing development of material science, promoting innovation in both industrial and academic settings.