Enhancement of Material Handling System for Optimized Safety Measures

Keywords:

Material Handling, Ergonomics, Semiconductor Manufacturing, SMEs, Safety Measures, FlexSim Simulation, Autonomous Mobile RobotsAbstract

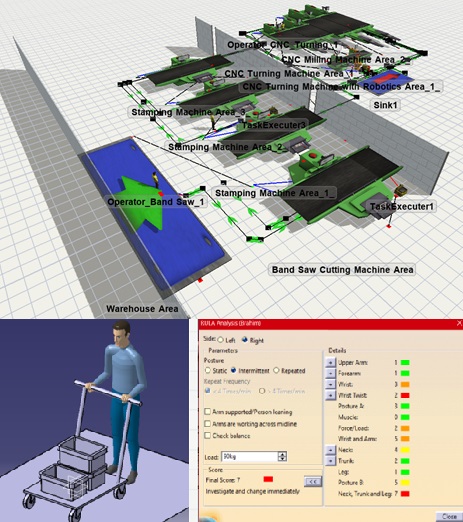

Material handling is a fundamental operation in industrial environments, especially among small and medium-sized enterprises (SMEs) like FAMAX Technology (M) Sdn. Bhd., where reliance on manual labor is high due to budget constraints. This study aims to enhance the safety and efficiency of material handling at FAMAX by optimized material handling and safety measures. The method that is used in this study is by site observation and layout mapping to identify current material handling activities. The analyzed time-motion studies, ergonomic assessments (RULA) and simulation FlexSim to identify physical strain of the workers. The result shows long-distance trolley handling and improper lifting postures. Practical and cost-effective solutions were proposed and validated, including the implementation of Autonomous Mobile Robots (AMRs) for long-distance transport and standardized safe work methods at critical points like the band saw cutting station. The interventions were validated through improved RULA scores, NIOSH lifting index calculations, and cost-benefit analysis. The results contributed directly to FAMAX by reducing ergonomic risk, improving workflow efficiency, and demonstrating a favorable return on investment. Overall, this study presents a scalable ergonomic improvement model for SMEs with similar resource constraints.