Computational Fluid Dynamic Modelling on Internal Flow Dynamics Using CFD in 90-Degree Bend Pipe

DOI:

https://doi.org/10.37934/afhme.6.1.1425aKeywords:

90-degree bend pipe flow, computational flow dynamic, flow separation, secondary flow, pressure distribution, velocity profiles, turbulent intensityAbstract

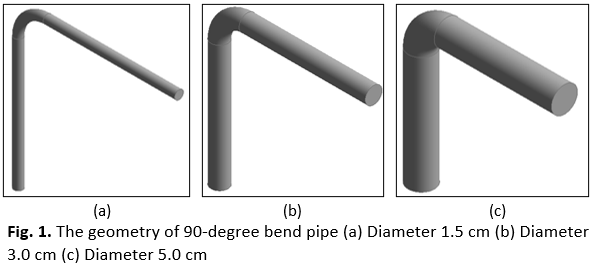

Computational fluid dynamics (CFD) is a powerful method for visualizing and analyzing fluid flow in pipes, helping engineers design more efficient systems. However, many earlier studies focus on just one pipe size or flow speed, which limits understanding of how different conditions affect flow. This study explores how varying pipe diameters (1.5 cm, 3 cm, and 5 cm) and inlet velocities (0.297 m/s, 0.397 m/s, and 0.497 m/s) influence velocity and pressure inside a 90-degree pipe bend. Using ANSYS Fluent, nine scenarios were simulated under steady, incompressible flow conditions by solving the Navier-Stokes equations with velocity inlets and pressure outlets. The results showed that the smallest pipe at the highest velocity had the fastest flow (up to 0.708 m/s) but also the largest pressure drop (254.68 Pa). Larger pipes displayed more uniform velocity distributions and significantly lower pressure losses. These findings clearly demonstrate how pipe size and flow speed affect fluid behaviour, emphasizing the importance of selecting appropriate pipe diameters to optimize flow efficiency and reduce energy loss in piping systems.