Simulation of Internal Flow Behaviour on the Different Diameter of Y-Junction Pipe

DOI:

https://doi.org/10.37934/afhme.6.1.5062aKeywords:

Y-junction pipe, computational fluid dynamics, pressure and velocity distributionAbstract

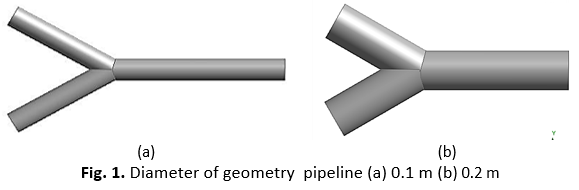

Pipelines are widely used in many industries for transporting water, chemicals, and other fluids, and their performance is strongly influenced by the behaviour of the fluid inside them. When a Y-junction is included in the pipeline, the flow is often affected by uneven speed, increased turbulence, and pressure losses. Although several studies have been conducted on flow in junctions, limited attention has been given to how pipe size and flow speed together influence the behaviour inside a Y-junction. In this study, this gap was addressed by examining how different pipe diameters and inlet velocities affect internal flow patterns. Computer simulations were carried out using ANSYS Fluent, where two pipe diameters (0.1 m and 0.2 m) and three inlet velocities (0.297 m/s, 0.397 m/s, and 0.497 m/s) were tested. From the results, it was observed that smaller pipes caused higher flow speed, greater turbulence, and a sharper pressure drop. In contrast, larger pipes produced slower and more stable flow with smoother pressure distribution. Through this analysis, useful insights were provided for improving the design of Y-junction pipelines, where better flow stability, reduced energy loss, and higher system efficiency can be achieved.